-

Glass Fused Steel Tanks (248)

-

Stainless Steel Bolted Tanks (148)

-

Fusion Bonded Epoxy Tanks (68)

-

Galvanized Steel Tanks (44)

-

Aluminum Dome Roofs (82)

-

Waste Water Storage Tanks (218)

-

Anaerobic Digester Tank (203)

-

Industrial Water Tanks (178)

-

Glass Lined Water Storage Tanks (181)

-

Bolted Steel Tanks (167)

-

Sludge Storage Tank (118)

-

Biogas Storage Tank (163)

-

Liquid Storage Tanks (173)

-

Leachate Storage Tanks (140)

-

Agricultural Water Storage Tanks (175)

-

Fire Water Tank (168)

-

Grain Storage Silos (119)

-

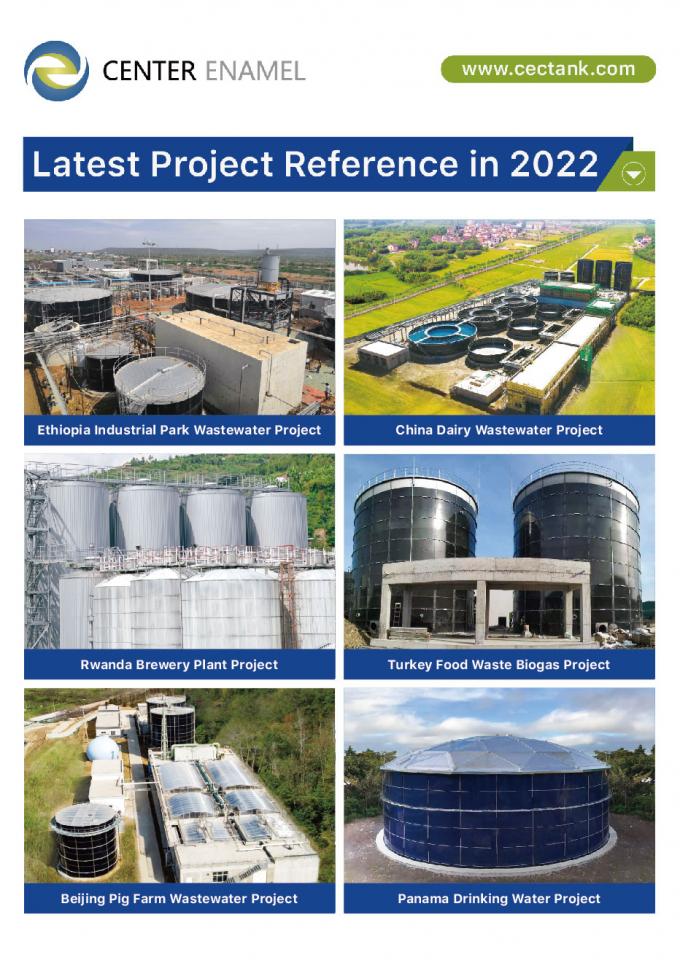

Biogas Plant Project (43)

-

Wastewater Treatment Projects (98)

Industrial 18000m3 Bolted Steel Tanks Double Coating

| Place of Origin: | China |

| Brand Name: | CEC TANKS |

| Certification: | ISO 9001:2008, AWWA D103 , OSHA , BSCI |

| Model Number: | W201609013 |

| Minimum Order Quantity: | 1set |

| Price: | $5000~$20000 one set |

| Packaging Details: | PE poly-foam between each two steel plates ; wooden pallet and wooden box |

| Delivery Time: | 0-60 days after deposit received |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60 sets per month |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | CEC TANKS |

|---|---|---|---|

| Certification | ISO 9001:2008, AWWA D103 , OSHA , BSCI | Model Number | W201609013 |

| Coating Thickness: | 0.25mm~0.40mm & Double Coating | Adhesion: | 3,450N/cm |

| Service Life: | ≥30 Years | Holiday Test: | >1500v |

| Elastic: | Same As Steel Sheet ,around 500KN /mm | Capacity: | 20 M3 To 18,000 M3 |

| High Light: | 18000m3 Bolted Steel Tanks,Industrial Bolted Steel Tanks,Bolted Steel Tanks Double coating |

||

Product Description

Center Enamel is a leading bolted steel tank manufacturer in China

Center Enamel is a leading bolted steel tank manufacturer in China, focusing on product innovation, customer service and product quality. Our bolted steel tanks offer unmatched assembly times, minimal field impact, and long life cycles.

Our bolted steel tanks are manufactured under the strictest quality process controls in an ISO 9001:2008 certified facility, designed using the latest engineering tools and supported by our experienced project management team. Our bolted steel tanks eliminate the need to coat the tank on site and ensure a high-quality finish to fully protect the steel from corrosion. With proper maintenance, our bolted steel tanks can last up to 30 years, providing lower overall life cycle costs. Our bolt pots consist of replaceable panels so maintenance, relocation, expansion and export have never been easier.

Bolted steel tanks are constructed from individual steel plates that are fabricated and finished in an enclosed facility, then shipped to the site and bolted together using appropriate washers and fasteners for the product to be stored. Unlike traditional concrete or welded storage solutions that require extensive on-site fabrication and finishing processes, bolted storage tanks provide quick installation, reduce shipping costs, and can be assembled in virtually any type of weather, eliminating many weather-related delay.

Bolted steel tanks are versatile and can be used in many industrial, commercial, residential, municipal and rural applications. They can be assembled from a variety of materials, such as powder coated, galvanized, or stainless steel, and they are available in a variety of sizes that can be tailored to the specific requirements of a project. They provide durable, leak-free storage solutions that are quick to install, easy to maintain, and an economical alternative to other tank designs.

What are the advantages compared to other tank types?

Bolted steel tanks are versatile and offer several advantages over competing tank designs such as concrete, welded steel, plastic or composite materials. Some of the most important benefits include:

Versatile Applications: Bolted steel tanks can be used in virtually any industrial, commercial, residential or rural application, from small manufacturing facilities and municipal water systems to full-scale frac sand plants and more. They meet or exceed multiple industry specifications, including AWWA, NFPA, API.

Flexible Sizes: Tank sizes are very flexible and bolted steel tanks can be customized to meet the capacity and installation requirements of any project and overcome site constraints.

Expansion Possibilities: Bolt tanks can often be expanded to meet increased storage needs without the added costs associated with a second tank.

Ease of Repair: When parts or accessories on the bolted steel tank fail, it can be easily removed and replaced, unlike other tanks that require extensive manual repairs.

Factory Completion: The various sections of the bolted steel tank are fabricated and completed off-site, reducing installation labor, waste and pollution, and weather delays during construction.

Reduce transportation costs: Bolted steel tanks are disassembled for transportation, reducing transportation volume and cost.

Faster Installation: Bolted steel tanks take about one-third the installation time of welded tanks, reducing labor costs and getting tanks into service faster.

Applications of Bolted Tanks

These tanks are commonly found in industrial, commercial, residential applications ranging in size from a few 100 bbls to 10,000 bbls. The most common applications of bolted tanks are listed below:

Water Sector: Storage of Drinking or Potable Water, Rural Water Districts, Subdivision/Private Water Systems, Water Storage at Municipality, Fire Protection Systems, Waste Water, Finish Water, Process Water, Disinfection, Filtration and Sludge Storage.

Food Industry: Salt factories, Flour & Sugar industries, Meals: Soybean, Bone, Fish, Corn, Meat, Blood, Dried Distillers Grain, Starch, Milk Solids, etc

Mineral Storage: Talc, Lime, Bentonite, Calcium Carbonate, Alumina, Gypsum, Silica, Coal, Phosphates, etc

Petroleum Products: Drilling Fluids, Crude Oil Storage, Mud, Fuel Oil, etc

Chemical Storage: Carbon Black, Cement, Activated Carbon, Sodium Nitrate, Fly Ash, Urea Pellets, Sodium Carbonate, Glass, Soda Ash, Potassium Carbonate, etc

Storage of Bio-Fuels: Caustics, Glycerin, Syrup, Bulk Bio-Diesel, Methanol, Yeast Tank, Raw Feedstock Oils, etc.

Power generation Industry: Treatment Bins & Silos, Coal Storage, Desulphurization Systems, Fly Ash Storage, etc

Our Water Storage tanks

| Storage tanks | Volume | Roofs | Accessories | Application |

| GFS Tanks SS Tanks Steel Tanks |

20-20000m³ | ADR Roof GFS Roof Membrane Roof FRP Roof Trough Deck Roof |

Ladders Platforms Pumps Three-phase Separator Biogas Purification System |

Wastewater Treatment Project Drinking Water Project Municipal Sewage Project Biogas Project Fire Water Storage Project Oil Storage Project |

About Center Enamel

Center Enamel is the leading bolted tanks and roofs manufacturer in China, which have more than 30 years of industry experience. Our main products include Glass-Fused-to-Steel tanks, stainless steel tanks, Carbon Steel tanks, aluminum geodesic dome roofs, and can provide customized design, manufacturing, and installation for global customers.All our products are in strict accordance with AWWA D103-09, API 650, OSHA, ISO 28765, NSF/ANSI 61, NFPA and other international standards. Until 2022, Center Enamel storage tanks and roofs have been exported to more than 90 countries including the USA, Australia, Canada, Malaysia, Indonesia, Russia, UAE, Panama, Brazil, and South Africa etc.

- Aluminum Geodesic Dome Roofs

- Stainless Steel Bolted Tanks Epoxy-coated Steel Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer